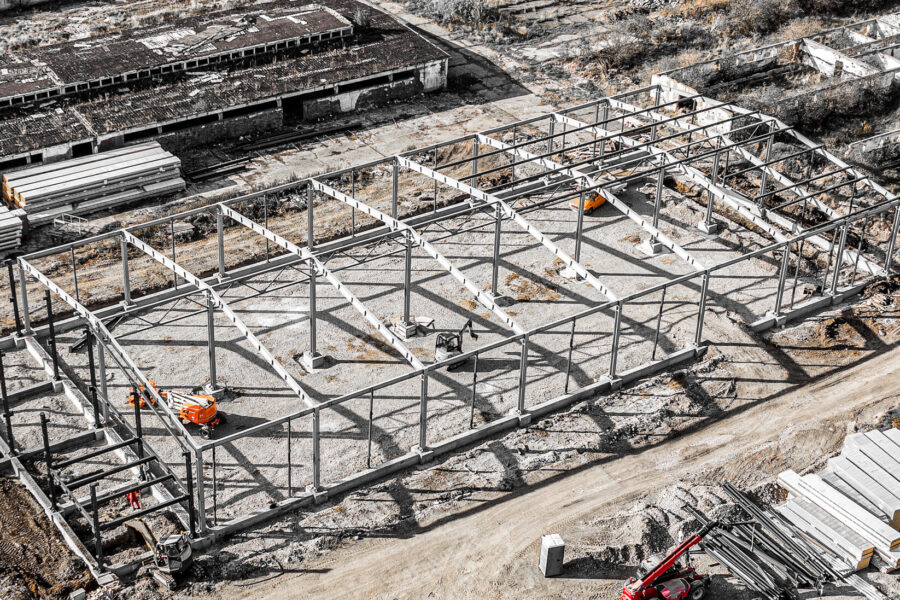

The Structural Steel Industry Is Changing... Are You Ready?

Structural steel fabricators face intense pressure: tight deadlines, rising material costs, and a skilled labor shortage. Manual welding and layout work can lead to bottlenecks, inconsistencies, and safety risks putting your project timelines and margins at risk.

Our Solution

– AGT helps leading fabricators automate their workflow from layout to welding.

– Automated layout and fit-up reduces human error and speeds up prep time.

– Robotic welding systems deliver consistent, high-quality welds on every part.

– Advanced vision systems handle part variability without manual intervention.

– Modular solutions fit your current workflow, with minimal disruption.

BeamMaster: Built Specifically for Structural Steel Fabricators

The BeamMaster is purpose-built for the realities of structural steel fabrication. Powered by our advanced Cortex software, it features auto-programming capabilities, eliminating the need for skilled robot programmers and dramatically reducing setup time. Whether you’re welding large, heavy, or extra-long beams, the BeamMaster handles it with ease—supporting profiles like C-sections, HSS, and complex geometries. It also manages a wide range of challenging connection types, from stiffeners to double-decker and crane beam connections. With its best-in-class weld quality and modular configurations, BeamMaster adapts to your workflow and scales with your production needs, making it the most versatile robotic welding solution for structural steel on the market.

BeamMaster vs. Traditional Welding and Other Robotic Solutions

| Feature | BeamMaster | Manual Welding | Generic Robotic Systems |

| Programming Time | None | N/A | High |

| Weld Types Supported | ⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐ |

| Material Quality | Can weld on rusty beams | Requires prep | Requires prep |

| Operator Skill Level | Low | High | High |

| Configurability | High | Medium | Low |

Proven Results from Real Fabricators

See how structural steel manufacturers like you are transforming their operations with the BeamMaster. From solving labor shortages to doubling output, our clients are experiencing real-world gains in productivity, quality, and consistency without the need for skilled robot programmers. Don’t just take our word for it, hear it directly from the fabricators who’ve made the switch to robotic welding for structural steel.

FAQ

What is robotic steel fabrication, and how does it apply to structural steel?

Robotic steel fabrication refers to the use of automated systems, like AGT’s BeamMaster or BLOK, to handle tasks such as cutting, welding, and assembling steel components. In structural steel fabrication, these systems streamline the production of large parts like steel beams and columns, reducing manual labor, increasing throughput, and ensuring consistent quality.

Can a welding robot handle complex steel beam welding?

Yes. A modern welding robot, especially AGT’s beam welding solutions, can handle steel beam welding with high precision, even on non-repetitive or complex geometries. With features like the SnapCam and offline programming, they adapt to a wide variety of beam types and configurations.

What are the advantages of using a robotic welding machine for structural steel?

Using a robotic welding machine in structural steel fabrication offers several benefits:

– Faster production cycles

– Consistent, high-quality welds

– Reduced reliance on manual welders

– Lower production costs over time

– Easier compliance with welding standards

These advantages make robotic systems ideal for fabricators producing metal beams in medium to high volumes.

Which AGT system is best for beam fabrication?

For beam fabrication, AGT offers specialized solutions:

– BeamMaster: Ideal for large, repetitive steel beam projects

– BLOK: Flexible for high-mix, low-volume welding of diverse structural parts

These systems are recognized among the best welding robots for structural applications due to their adaptability and productivity.

Can a robotic welding system work for custom or one-off beams?

Absolutely. AGT systems are engineered for flexibility. With automatic welding robot programming features and offline simulation, fabricators can switch from project to project without costly downtime, perfect for shops working with varied or custom steel beam welding jobs.

What types of steel structures can be welded with AGT’s beam welding robots?

AGT’s beam welding robots are designed to handle a wide variety of structural components:

– I-beams and H-beams

– Box beams and tubular steel

– Welded girders and frames

– Complex multi-component assemblies

Our systems support fabricators serving construction, infrastructure, and industrial sectors.

How does robotic welding improve consistency and reduce rework?

Robotic welding metal beams ensures consistent travel speed, arc performance, and torch angles resulting in fewer defects. Unlike manual welders who may vary between shifts or operators, a robotic welding machine delivers the same high-quality results every time.

Advanced Structural Steel Solutions

Optimize Efficiency with Automation

Want to see how AGT helps you take on more work without hiring more welders? Let’s talk.