-

Automated With Cortex Prime

Cortex offers a genuine no-programming solution. Initiate the program creation process for an entire assembly with just a few mouse clicks, resulting in hundreds of unique robot programs generated completely automatically in minutes.

-

Modular Welding Systems

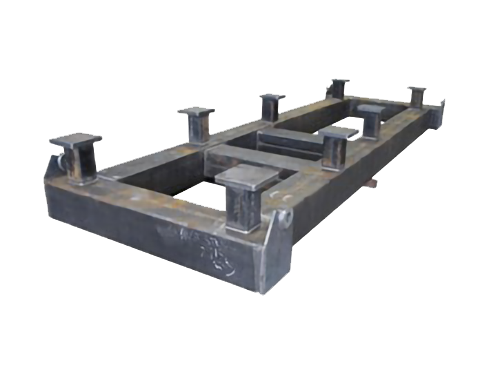

BLOK Systems are fully modular, enabling fabricators to tailor the perfect welding setup for varying applications and adapt as business needs evolve

-

Versatile Fabrication

BLOK cells efficiently handle heavy fabrication assemblies, including those requiring complex multi-pass welds, demonstrating significant versatility in robotic welding applications.

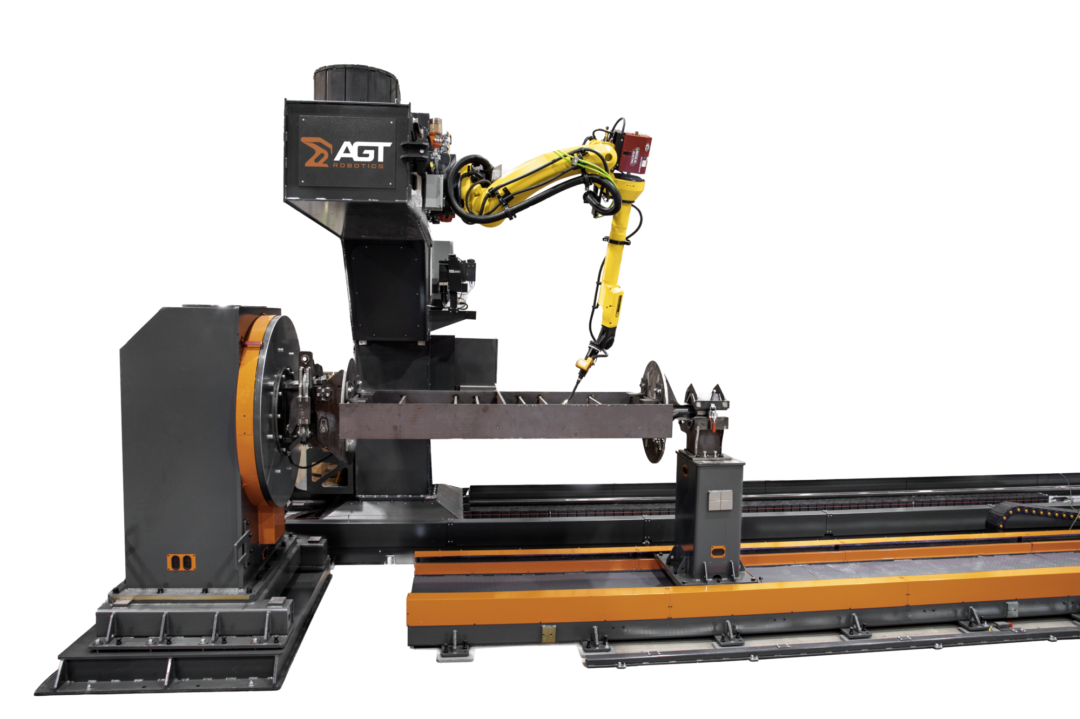

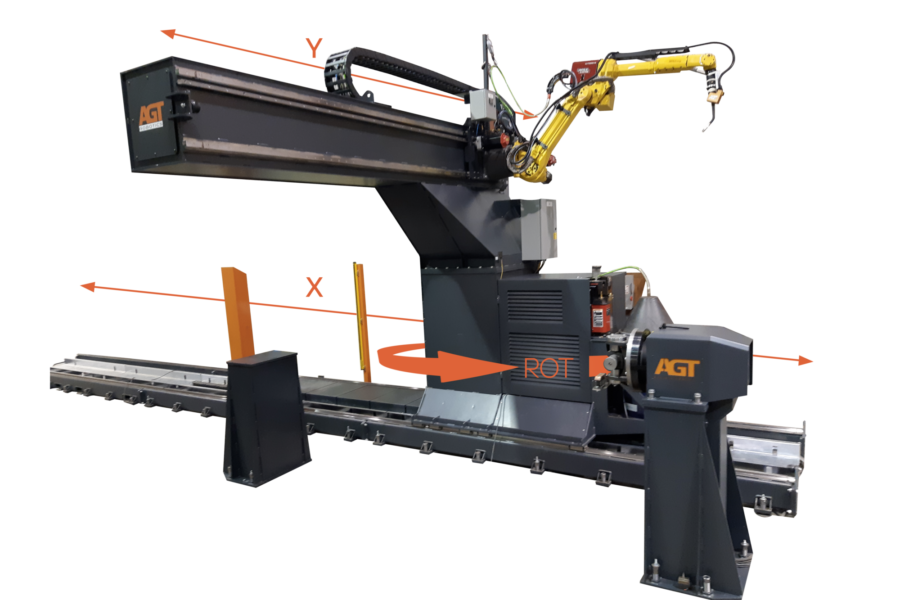

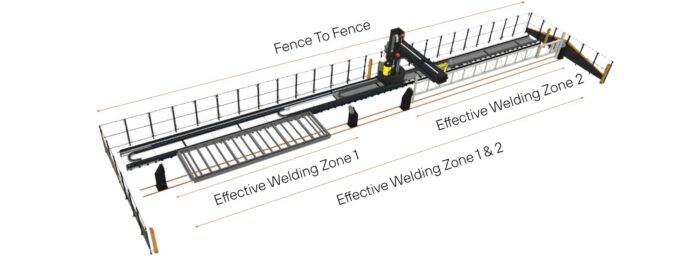

BLOK 400

The BLOK 400 is a robust, modular robotic welding system designed specifically for heavy fabrication needs. Its design includes X-axis and Y-axis movement on rails, allowing it to handle larger components efficiently. This advanced setup makes it ideal for fabricating a variety of large structures such as skids, trailers, and frames, providing extensive coverage and precision in complex welding tasks. The BLOK 400 can also be equipped with optional rotation, making it the perfect solution for demanding fabrication environments.

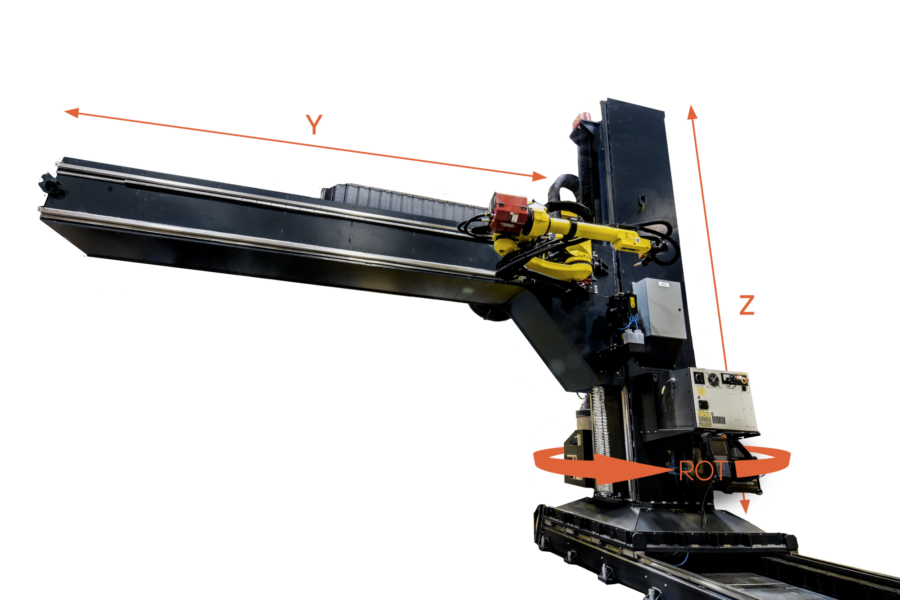

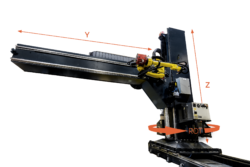

BLOK 500

The BLOK 500 is a highly advanced modular robotic welding system tailored for complex heavy fabrication tasks. It incorporates three-axis mobility (X, Y, and Z), enabling the welding column to move vertically to access deeper parts. This capability is perfect for welding larger and more intricate items like railcars, containers, and heavy machinery components. For enhanced reach and flexibility, the BLOK 500 also offers optional rotational movement, making it a versatile choice for demanding welding requirements.

Tech Specs

Dimensions

|

||

| imperial | metric | |

|---|---|---|

| Fence To Fence | 77’ | 23.51 m |

| EWZ 1 | 26’ | 7.89 m |

| EWZ 2 | 26’ | 7.89 m |

| EWZ 1 & 2 | 65’ | 19.98 m |

| Height | 12’ | 3.7 m |

Part Tolerances

Infeed beams and sections must be of good quality and must respect the following criteria:

- Flatness = up to 2 mm (0.09’’)

- Cut straightness = up to 2 mm (0.09’’)

- Cut angle = ±2 mm (0.09’’)

- CAD vs Actual for all dimensions = up to 4 mm (0.16’’) deviation

Deliverable

Axis System

|

||

| 1a | Option 1a: AGT BLOK 400 Robot Cantilevered Gantry

|

|

| 1b | Option 1b: Same as above with rotation axis |

|

|

||

| 2a | Option 2a: AGT BLOK 500 Robot Cantilevered Gantry

|

|

| 2b | Option 2b: Same as above with rotation axis |

|

Positioners

| Qty | ||

|---|---|---|

| 1a | Option 1a: No Positionners

|

✓ Included |

|

Qty | ||

|---|---|---|---|

| 1b | Option 1b: Headstock / Tailstock

|

✗ Optional |

|

|

Qty | ||

|---|---|---|---|

| 1c | Option 1c: AGT Structural Steel Beam Rotators

|

✗ Optional |

|

Robotic

|

Item | Description | Qty |

|---|---|---|---|

| 1 | Welding Robot – Fanuc ARC Mate 120iD/12L with R-30iB+ controller

|

✓ Included |

|

Item | Description | Qty |

|---|---|---|---|

| 2 | Automation and interface

|