Configurations to Suit Your Shop

-

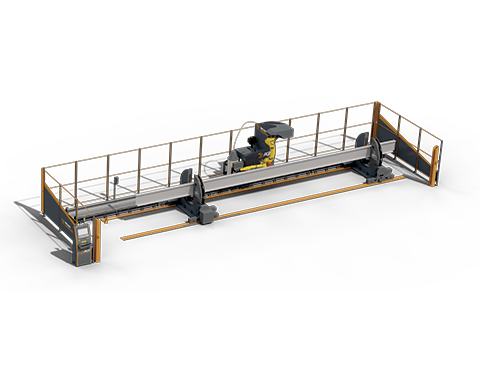

Light: Compact Efficiency

A single-zone robotic welding system with trestles, ideal for smaller shops. Optional rotators available for enhanced versatility.

-

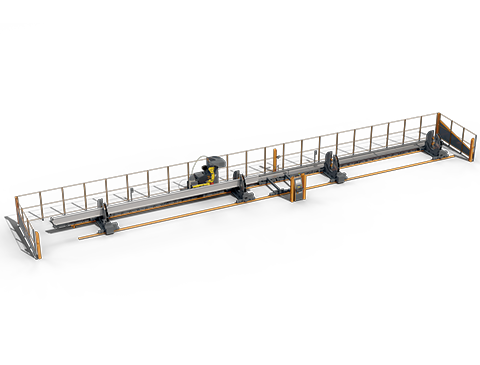

Plus : Dual-Zone Versatility, One Robot

The standard two-zone robotic welding solution with rotators, delivering increased productivity and fully automated workflows.

-

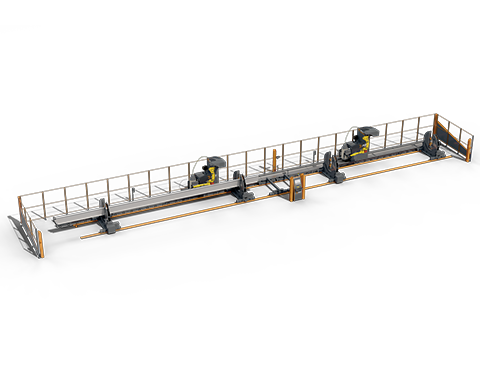

Twin : Maximum Optimization

A dual-robot robotic welding system designed for maximum throughput, handling large-scale production with ease.

What is the BeamMaster?

The BeamMaster is an advanced robotic welding system designed to automate structural steel fabrication with unparalleled efficiency. Simply send a pre-fit beam to the machine, and it completes the required welds in a fraction of the time compared to manual welding. Equipped with optional beam rotators, the process becomes fully autonomous, ensuring perfect horizontal positioning for every weld. Its award-winning CORTEX software allows for cost-effective robotic welding, even with lot sizes as small as one, breaking the traditional barriers of needing large volumes of identical parts to justify automation. BeamMaster revolutionizes productivity and precision in structural steel fabrication.

Eliminate Unnecessary Handling

The BeamMaster, equipped with CORTEX auto-programming and beam rotators, eliminates unnecessary handling during the welding process. Simply position the beam, and the system takes over, autonomously rotating and welding with precision. This automation minimizes manual intervention, streamlining the workflow and significantly reducing labor time. With BeamMaster, you can focus on productivity while the machine handles the rest, ensuring consistent, high-quality welds with minimal handling.

Tech Specs

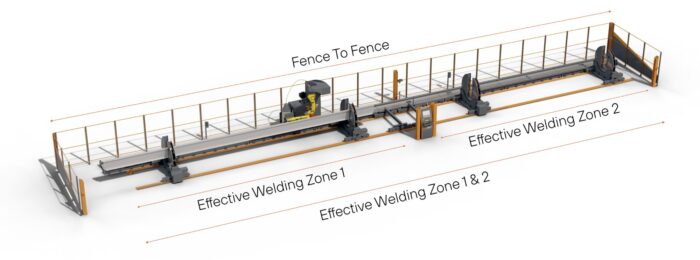

Dimensions

|

||

| Imperial | Metric | |

|---|---|---|

| Fence To Fence | 112’ | 34.1 m |

| EWZ 1 | 40’ | 12 m |

| EWZ 2 | 40’ | 12 m |

| EWZ 1 & 2 | 92’ | 29 m |

| Height | 13’ | 3.95 m |

Welding Specifications

| Fillet welds (2f) |

20.0 in/min for 3/16’’ weld

15.0 in/min for 1/4’’ weld

10.0 in/min for 5/16″ weld

Speed may be increased if fit-up allows.

|

(8.4 mm/s for 4.8 mm fillet weld)

(6.4 mm/s for 6.4 mm fillet weld)

(4.6 mm/s for 8 mm fillet weld) |

| Gap detection | No gap detection | |

| Joint detection | 3D Camera Point Cloud seam finding (SnapCam) | |

| Process and position | MCAW – Spray and pulse transfer modes / BS EN ISO 4063 Process 138 GMAW – Spray and pulse transfer modes / BS EN ISO 4063 Process 135 |

|

| Welding wire | CAW: A5. 18, A5. 18M: E70C-6M H4 / CSA W48-06: E491C-6MJ-H4 GMAW: A5. 18, A5. 18M: ER70S-6 / CSA W48-06: B-G 49A 3 C1 S6 |

|

| Approved Filler Metals |

Preferred:

MCAW: Hobart Fabcor Edge 0.045″ diameter (1.2 mm)

Alternative:

GMAW: Lincoln Electric SuperArc L-59 0.045″ (1.2 mm)

|

|

| Shielding gas | 85%Ar-15%CO2 mix (M20) 90%Ar-10%CO2 mix (M20) |

|

| Surface finish | All parts and beam must be clean with no excessive rust or mill scale. Database includes procedures for both Sandblasted surfaces and mill scale. Highest quality is obtained on Sandblasted surfaces. Slower welding speed are used for Mill scale surfaces. |

|

Parts Specifications

W Beam

| Imperial | Metric | |||

|---|---|---|---|---|

| Section | Min. | W6 x 14 | W150 x 22 | |

| Max. | W48 | W1220 | ||

| Length | Min. | 12’ | 3.62 m | |

| Max. (2 zones) | 80’ | 24.4 m | ||

HSS Closed Rectangular Column

| Imperial | Metric | |||

|---|---|---|---|---|

| Section | Min. | 6″ x 6″ x 0.188 | 152 x 152 x 4.8 mm | |

| Max. | 20″ x 20″ | 558 x 558 mm | ||

| Length rotators | Min. | 12’ | 3.62 m | |

| Max. (2 zones) | 80’ | 24.4 m | ||

| Length trestles | Min. | 4’ | 1.21 m | |

| Max. | 50’ | 15.2 m | ||

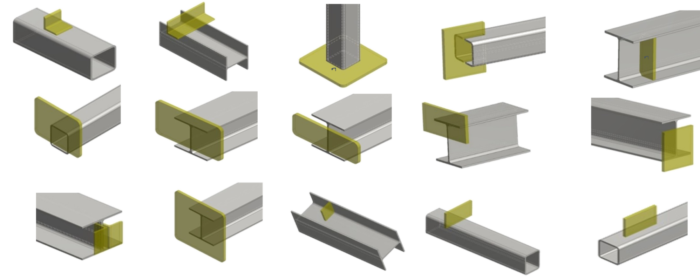

Also Supports

MILL SHAPES

|

|

FABRICATED BEAMS

|

|

OTHER ASSEMBLIES

|

|

Connectors

…and more!

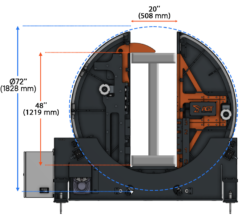

Rotators Specifications