Why ETS Bobet Chose the BeamMaster

Company Director Damien Bobet recognized that automation wasn’t just about keeping up with demand—it was about creating a sustainable future for the business.

- Addressing Labor Shortages – Finding skilled welders was becoming increasingly difficult. With automation, existing welders could focus on higher-value tasks, while the robot handled repetitive welding work.

- Reducing Physical Strain on Workers – The BeamMaster’s automated welding process significantly reduced manual handling, making it easier for employees to operate efficiently, even during peak summer heat.

- Boosting Productivity & Winning More Contracts – Welding a structural column by hand required two welders for two hours.

With the BeamMaster, the same job is completed in just 50 minutes—a 58% reduction in welding time. This improvement allowed ETS Bobet to take on weekly contracts they previously couldn’t manage.

Seamless Integration with Digital Workflows

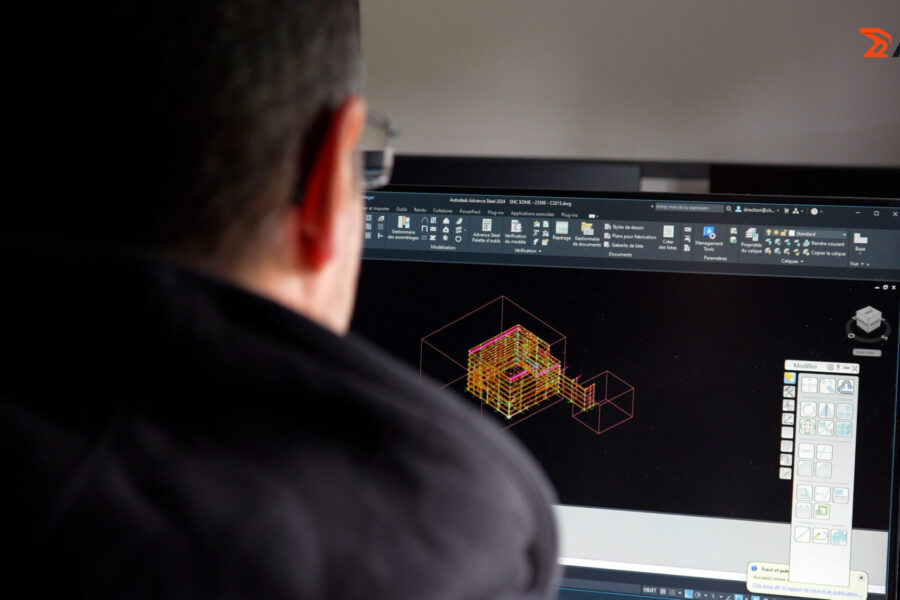

Welding automation is only effective if it fits within an efficient digital workflow. That’s why ETS Bobet integrated Advance Steel and Cortex software to streamline fabrication from design to welding execution.

Step 1: Create CAD Model – Engineers use Advance Steel or Tekla to design the full structure.

Step 2: Export IFC File – The design is exported as an IFC file and sent to Cortex.

Step 3: Automated Intelligent Welding – Cortex automatically generates the robot’s welding path.

Step 4: Efficient Production – Large projects are easily split into manageable sections, ensuring a smooth, optimized workflow.

The BeamMaster in Action: Robots & Welders Working Together

One of the biggest misconceptions about automation is that robots replace workers. At ETS Bobet, the BeamMaster enhances the workforce rather than replacing it.

The BeamMaster handles repetitive, long welds, ensuring precision and consistency.

Skilled welders focus on complex assemblies, optimizing their expertise where it matters most.

Production output has increased by 35%, with improved weld quality and reduced rework.

A Future Built on Automation

With the BeamMaster fully integrated into production, ETS Bobet is now looking toward the future. The next step? Running a two-shift operation, maximizing their investment in automation, digital workflows, and skilled employees working alongside robotic systems.

As Damien Bobet puts it:

“Our future is growing stronger every day. With the BeamMaster, we’re optimizing every step of our production and embracing a new era of welding automation.”

Full Testimonial

Want to see how ETS Bobet transformed their welding process with automation? Watch the full testimonial on YouTube and hear firsthand how the BeamMaster is boosting productivity and efficiency!

Is Welding Automation Right for Your Business?

If you’re facing labor shortages, increasing production demands, or looking to improve welding efficiency, AGT Robotics can help. Discover how our solutions can transform your workflow—just like they did for ETS Bobet.

Contact us today to schedule a consultation!

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.