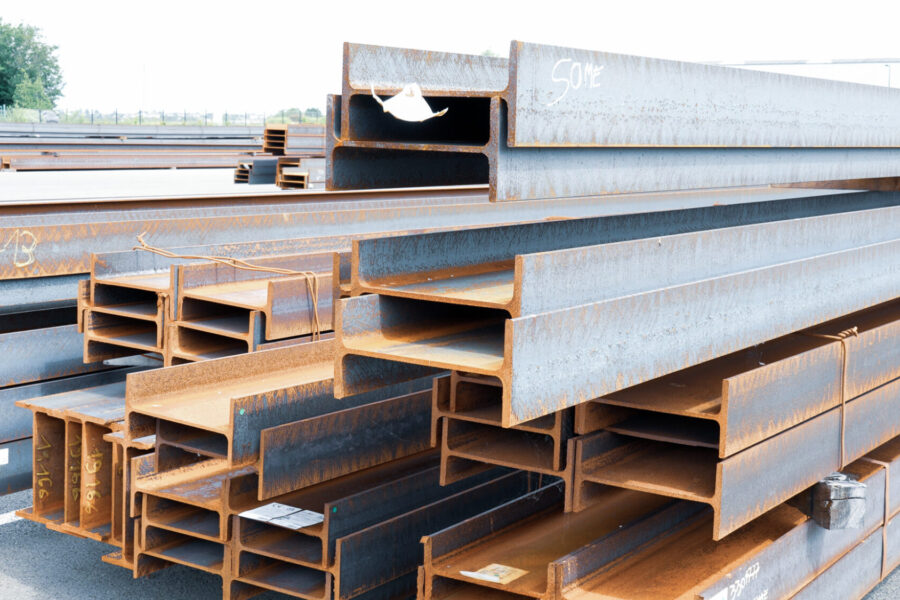

The Hidden Costs Of Welding Over Mill Scale

Most manufacturers, especially in North America, skip surface cleaning because it’s seen as non-essential or too expensive.

Yet neglecting this step leads to a cascade of consequences:

- Arc instability caused by non-adherent mill scale.

- Irregular visual results: convex welds, increased presence of silica islands, underfilled welds.

- Systematic oversizing (up to ±25% more filler metal) just to compensate for poor preparation.

- Increased deformation from excessive heat input.

- Slower welding speeds due to more conservative recipes.

- Lower overall productivity, higher costs, and welds that fail to meet industry standards (CSA, AWS).

Even with a high-performance welding robot like the BeamMaster, optimal results are impossible without proper surface conditions. Automation can’t make up for non-compliant input.

Clean Surfaces Equal Quality Welds And Profits

Thankfully, achieving perfect cleanliness isn’t mandatory. There’s a middle ground between full blasting and doing nothing.

Here are the top recommendations based on AGT Robotics’ field experience:

Understand The standards And Follow Them

Canadian (CSA W59), American (AWS D1.1) and European (EN 1090) standards allow welding on light, adherent mill scale if it can withstand vigorous wire brushing. Once scale starts flaking off, welding is no longer permitted. These standards also require cleaning within two inches of the weld on all sides.

Target The Critical Zones

You don’t need to blast the entire part. Simply grinding around the joint (about 1’’ on each side) is often enough to achieve uniform wetting, cleaner welds, less filler metal, and better weld geometry.

Tailor Your Recipes To The Reality On The Shop Floor

At AGT, BeamMaster programs are designed to slightly compensate for dirty joints, rust, and poor fit-up. But this comes at a cost: slower welds and larger beads. If surfaces were better prepared, weld speeds could increase by 15-20%, while reducing filler usage and deformation.

Consider Practical Alternatives

If blasting isn’t feasible (due to storage, humidity, or queue times before painting), consider:

- Spot grinding near the weld.

- Implementing pre-weld prep steps inline with the robot.

Adjust Your Expectations of Automation

Human welders can adapt in real time. Robots cannot. They execute the program exactly as written. If conditions vary, recipes must compensate usually at the expense of speed, material, and quality. True automation success depends on consistency from the start.

Less Scale, More Performance

Welding robots like the BeamMaster are powerful tools but only if they receive quality input. A poorly prepared surface leads to:

- Overwelding and excess filler

- Irregular results

- More defects

- Lost productivity and speed

Surface preparation isn’t a cost, it’s a quality guarantee.

In Summary

- Clean surfaces reduce filler usage.

- Regular welds reduce defects and rework.

- Consistency enables automation to deliver its full promise.

Proper surface preparation lays the foundation for high‑performance robotic welding.

It’s not a luxury, but a prerequisite for success. Well‑designed automation always begins with consistency at the source. And that consistency inevitably depends on a clean, stable, and compliant surface.

So, are you ready to give your robots the conditions they deserve?

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.