Why “Peak Manual Welding” Is Not The Same As Production Consistency

Manual welding at its finest is real craftsmanship. A great welder can produce beautiful work. However the challenge is not capability. The challenge is repeatability.

High-quality manual welding requires short-duration, high-focus performance. That level of concentration is hard to maintain hour after hour, shift after shift, especially when the shop is busy and deadlines are tight. When focus drops, what usually changes first is not intention, it is the small details: pace, consistency, and repeatability on production pieces.

This is not a knock on welders. It’s the reality of human performance. Manufacturing systems should be designed around that reality and embrace the tools to increase output in a meaningful way.

That is where man & machine becomes a practical solution, not a philosophy.

Capacity: Stop Capping Throughput On Human Endurance

Most shops don’t have a “welding skill” problem. They have a welding bottleneck problem.

Capacity gets limited when:

- The shop cannot hire enough welders to meet demand.

- Arc time is low because the day is full of stops, starts, repositioning, and rework.

- Cycle time varies too much and increases output variability.

- The fastest path becomes “work harder,” which is not a strategy.

Robots help because they’re built for repeatable execution over extended time frames. When the weld is repeatable and accessible, the robot can keep the torch moving with the same pace and discipline all day.

The biggest capacity gain I see is not just “faster welding.” It’s the ability to plan around a process that behaves the same way on Tuesday afternoon as it does Monday morning.

Consistency: The Real Quality Problem Is Variation Over Time

A lot of discussions focus on peak quality. Production problems usually come from inconsistency which leads to decreased welding speed, rework, quality control issues, missed deadlines, and cost overages.

Here is what I see in many manual welding environments under pressure. Fatigue kicks in or their focus slips, people often compensate by slowing down or adding weld to avoid an error. That’s a rational human response. Nobody wants a callout for under-welding.

The tradeoff is that the shop pays for it:

- More wire and gas

- More time per part

- More heat input and potential distortion

- More variability in weld profile and appearance

- More rework and less predictable output

Robotic welding, used correctly, establishes a stable baseline. It produces the same weld size and profile repeatedly, which speeds visual inspection and reduces surprises later in the production or erection process.

Control: Predictable Performance Comes From Controlling Inputs And Exceptions

Control is the most overlooked part of automation. There’s a huge difference between “we installed a robot” and “we can count on the results.”

In real shops, variability shows up everywhere. Parts don’t always match the drawing. Fit-up changes depending on who’s doing it, what shift it is, and how rushed the job feels. Tolerances stack up. Upstream cutting and coping decisions ripple all the way to the weld.

Here’s the blunt truth: robotic welding won’t fix upstream inconsistency, and when those inputs aren’t stable, the robot takes the blame.

The best performance comes when the team and the robot work together: solid part prep, repeatable fit-up, and reliable location in the fixture. Give it consistent inputs and it will give you consistent results.

What Manual Welding Is Best At

There are jobs where a skilled welder is simply the right tool for the work. Manual welding excels when the task demands real-time decision-making and adaptability.

Manual welding is best for:

- Tight access and awkward positions.

- Complex parts and accessories.

- One-off work where standardization does not make sense.

- Judgment calls in the moment to manage gaps, heat input, and joint condition.

Welders add value through intelligence.

What Robotic Welding Is Best At

Robots are extremely good at repeatability. That matters because repeatability supports capacity planning, consistent quality, and stable execution when manufacturing high-mix and low volume outputs.

Robotic welding is great for:

- Repeatable joints and consistent geometry.

- Longer welds and high arc time.

- Stable torch angle and travel speed requirements.

- A need for predictable results across shifts.

- A desire to reduce over-welding and variability.

Robots aren’t there to replace skill. They’re there to remove the dependence on human endurance for repeatable work and provide valuable data used in production planning and cost control.

The Balance That Works In Practice

In many shops, the winning workflow looks like this:

- People handle fit-up decisions and exceptions.

- A fixture and standards lock in repeatability.

- The robot executes the repeatable weld content.

- People handle special joints, finishing, and non-standard work.

In a healthy man & machine shop, your best welders don’t become less important. They become more important. They help define the process, validate outcomes, train others, and solve the difficult problems that the robot should not be forced to solve.

Final Thought: It’s Not A Contest

This is not man versus machine.

It’s man and machine, used intentionally. Manual welding brings value through human skill, intelligence and experience, especially when parts are complex. Robotic welding excels at consistent, repeatable tasks, and with auto-programming solutions it becomes a strong fit even in high-mix, low-volume production. When you stop asking one to be the other, you can build a system that performs better than either approach alone.

If you want to explore whether a hybrid workflow fits your assemblies, AGT Robotics can help you assess the repeatability, fixturing approach, and process requirements before you invest.

FAQ

When I walk into a shop, a few indicators tell me whether man & machine is likely to deliver Capacity, Consistency, and Control.

1) Manpower constraint

Are you struggling to staff welders, or is growth capped by labor availability?

2) Upstream capability

Do your parts show up consistently? Cutting, coping, squareness, and prep matter.

3) Demand certainty

If you double your output, can you sell it?

4) Digital workflow maturity

Do you have a reliable CAD-to-shop-floor workflow, using tools like Tekla or SDS/2, with solid revision control and consistent, repeatable part definitions?

5) Space and layout reality

Can you integrate a system without breaking the shop flow?

If you said yes to two or more, you may be closer to automation than you think. You’re ready to chat with us and we’ll help you assess where you are today and what it takes to get your shop automation ready.

Start by picking the right target, not by shopping for a robot. Look for a family of weldments that’s repeatable, frame-like or modular, common enough to standardize, and painful enough today that fixing it would actually matter.

Then define what “success” means in shop terms: consistent weld size and appearance, less rework, predictable cycle times, and smoother scheduling with fewer surprises.

At AGT Robotics, the first step is usually a quick pre-qualification discussion. We look at your assemblies, variability, and workflow so we can tell whether a man and machine approach will genuinely stabilize output and quality. The goal isn’t to force a robot, it’s to make sure the application is a fit.

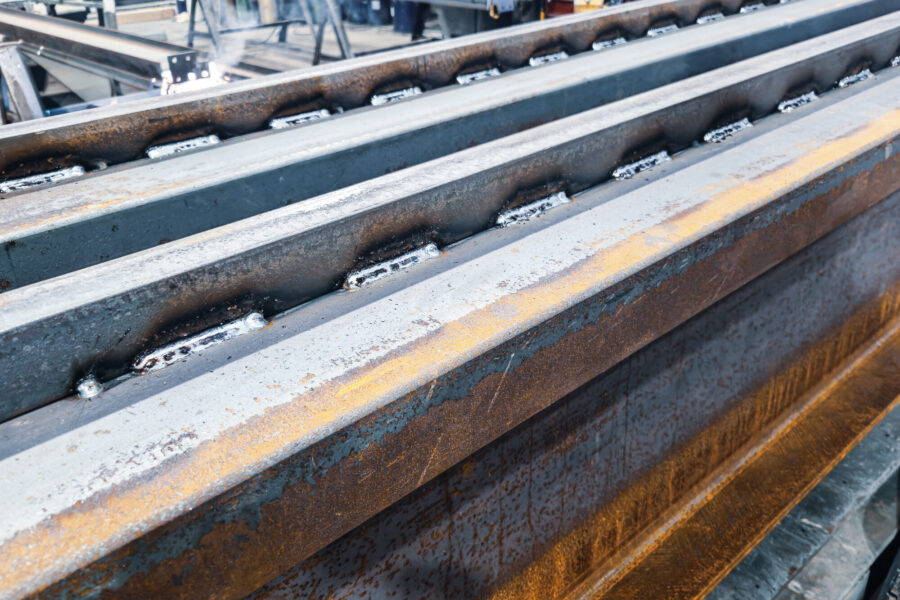

With AGT, strong candidates include structural steel beams and heavy fabrication assemblies such as cross-frames, trailers, trusses, and skids. If you already have 3D CAD models for these projects, you’re in a great position to explore ready-to-use, auto-programming robotic welding solutions.

In most successful shops, automation doesn’t replace welders, it reallocates their skill. The robot takes on repeatable weld content, while people focus on fit-up decisions, complex joints, exceptions, QA, and process improvement. The best outcomes happen when automation is treated as a capacity and consistency tool, not a staffing shortcut.

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.