A Legacy of Fabrication Excellence

Founded in 1973, Produits Métalliques AT is a second-generation family-owned business based in Matane, in the Gaspésie region of Quebec. The company specializes in the manufacturing of snow removal equipment, dump bodies, and trailers, serving customers across Canada from Halifax to Vancouver. It has built a strong reputation on the quality of its welded assemblies and its commitment to innovation in a highly competitive sector.

Welding Pressure, Workforce Gaps...

Before its shift to robotic welding, Produits Métalliques AT was facing several critical challenges. Among them was the difficulty of maintaining consistent weld quality while keeping up with rising demand. Compounding this was the growing shortage of skilled labor, a common issue in the manufacturing sector, especially in remote regions. The company needed a way to boost productivity without necessarily increasing headcount.

Why Automation Was the Next Step

To address these challenges, the company invested in a robotic welding cell. The main goal was to standardize operations in order to ensure consistent quality while increasing production capacity. This shift also prompted the team to rethink product design itself: now, every new piece of equipment is engineered with robotic welding in mind.

This technological leap also reshaped the company’s internal workflow. As Quality Director Jean-Philippe Côté explains:

“The system allows one welder to assemble parts while the robot simultaneously welds another dramatically boosting efficiency without compromising precision.”

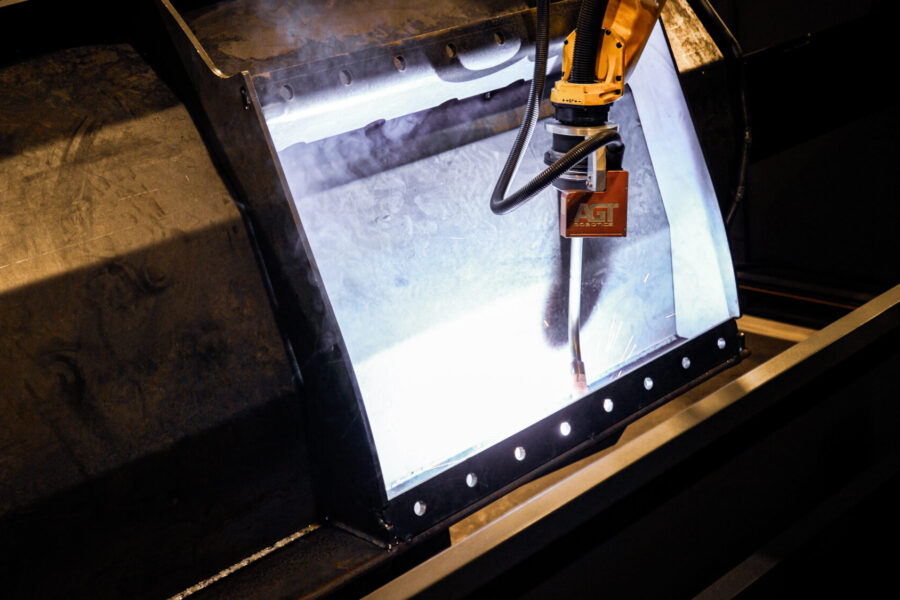

Implementation: The “Gaston” Cell

The robotic cell was named “Gaston” in honor of President André Tremblay’s late father. This name reflects both the company’s familial roots and its long-term vision. The project, executed in partnership with AGT Robotics, included everything from needs assessment and system integration to training and post-installation support.

Technology With Real Results

The impact of the robotic system has been concrete and measurable. The company has improved productivity, consistency, and overall weld quality. Processes are more standardized, which makes onboarding new employees easier and reduces the risk of errors.

From a human standpoint, robotization has allowed internal talent to grow by redefining roles. This repositioning has had a positive effect on both employee retention and the company’s appeal as an employer.

A Transformation Rooted in Vision and People

The story of Produits Métalliques AT is a powerful example of how a regional manufacturer can embrace cutting-edge technology without losing sight of its people or its roots. By partnering with a trusted expert like AGT Robotics, the company successfully overcame key challenges and positioned itself strategically for the future. The “Gaston” cell is more than just a machine, it stands as a symbol of transformation that is both technological and deeply human.

See It. Hear It. Believe It.

Want to hear the story directly from the people who lived it?

Watch the full video testimonial and discover how robotization transformed Produits Métalliques AT, told in their own words, from the shop floor to the leadership team.

Ready to Build Your Own Success Story?

Let’s talk about how robotics can work for you.

Whether you’re facing labor shortages, quality control issues, or just looking to scale efficiently, AGT Robotics can help you take the next step with confidence.

Our team is here to guide you from first concept to full production.

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.