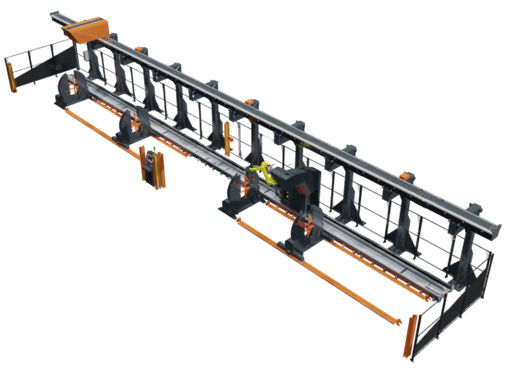

Powerful and Flexible Fitting Solution

-

Customizable to Suit Your Needs

The standard 40' configuration can expand in 10' increments, reaching up to 138' to meet production demands.

-

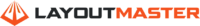

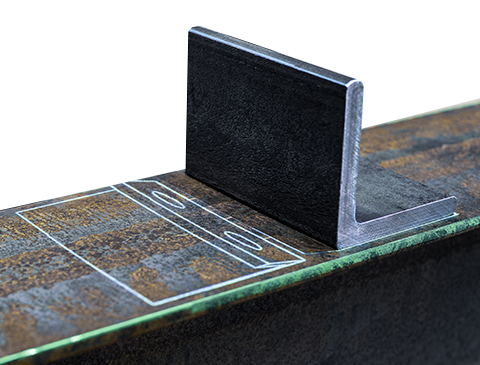

Full-Color Projection on Any Connection

LayoutMaster projects detailed data on various connection types such as base plates, angle seats and bearing pads, ensuring precise fitting.

-

HMI, Tablet, and Remote Control

Includes a rugged, detachable Wi-Fi touchscreen tablet, charging dock, and an 8-button industrial remote for easy operation.

What is the LayoutMaster

The LayoutMaster is a full-color laser projection system that will project all the information that an operator needs to precisely tack-weld connections on the beam or on other connections.

The LayoutMaster is the ultimate, common-sense tool to transform any operator into your best fitter in a matter of minutes!

Why Invest in a Projection System?

The typical steel fabrication shop spends between 20 & 30% of the entire shop fabrication time on fitting operations. Along with welding, it’s the most labor-intensive operation of the entire fabrication process.

You have likely invested in automated equipment for beam and part preparation; it’s now time to bring your shop to the next phase: Assisted Fitting.

Cortex for LayoutMaster

Cortex for LayoutMaster software allows fitters to work without the need for paper or tablet drawings. It precisely calculates and projects the position of accessories relative to the beam’s origin, ensuring accuracy.

Cortex for LayoutMaster converts Tekla and SDS2 models into projection-ready formats, making it adaptable to the needs of any fabricator.

Cortex can generate

- Welds in Catch All mode

- Stitch Welds

- Welds between coped section and accessories on IBeam

- Welds between coped section and accessories on HSS

Contact our team today to discover how you can seamlessly integrate the LayoutMaster and the power of Cortex into your production line.

Tech Specs

Dimensions

|

||

| imperial | metric | |

|---|---|---|

| Width | Min 40’ Max 138’ |

12 m 42 m |

| Height | 12’ | 3,65 m |

Configurations

Stand alone

With BeamMaster Plus

Parts Specifications

| Metric | Imperial | |||

|---|---|---|---|---|

| Width | Up to | 55’’ | 1397 mm | |

| Height | Up to | 70’’ | 1778 mm | |

| Width | Up to | 55’’ | 1397 mm | |

| Height | Up to | 70’’ | 1778 mm | |

| Width | Up to | 55’’ | 1397 mm | |

| Height | Up to | 70’’ | 1778 mm | |

| Width | Up to | 55’’ | 1397 mm | |

| Height | Up to | 70’’ | 1778 mm | |

| Width | Up to | 55’’ | 1397 mm | |

| Height | Up to | N/A | 1778 mm | |

CAD Input

| IFC EM11 |

IFC EM11 |

|||

|---|---|---|---|---|

| PLUGIN | PLUGIN | |||

| MAIN MEMBER TYPE | ||||

| W-Beam | ✓ | ✓ | ✓ | ✓ |

| HSS | ✓ | ✓ | ✓ | ✓ |

| Channel | ✓ | O | ✓ | ✓ |

| Fabricated Beam | ✓ | O | ✓ | ✓ |

| GENERAL FEATURES | ||||

| Supports Coped beams | ✓ | ✓ | ✓ | ✓ |

| Can Read Holes | ✓ | ✓ | ✓ | ✓ |

| WELDING INFORMATION | ||||

| Can read | ||||

| Weld Position | ✓ | ✓ | O | O |

| Weld Size | ✓ | ✓ | ✓ | ✓ |

| Multi-Pass information from CAD | ✓ | ✓ | ✓ | ✓ |

| Stitch Welds from CAD | ✓ | O | O | O |

| Cortex can generate | ||||

| Welds in Catch All mode | ✓ | ✓ | ✓ | ✓ |

| Stich Welds | ✓ | ✓ | ✓ | ✓ |

| …Welds between coped section and accessories on I-beam | ✓ | ✓ | ✓ | ✓ |

| …Welds between coped section and accessories on HSS | ✓ | ✓ | ✓ | ✓ |

| DELETE | ||||

| …Accessories in Cortex | ✓ | ✓ | ✓ | ✓ |

| …Welds in Cortex | ✓ | ✓ | ✓ | ✓ |

| LEGEND | |

|---|---|

| ✓ | Supported |

| O | Not included (but technically possible to add in future releases) |

| ✗ | Not supported |

Note :

Please contact us for SDS2, Tekla2, Advanced Steel, Tekla or Solidworks versions that are supported