Solve Welder Shortages with Less Training Required

Skilled welders are in short supply across North America. Between retirements, a limited pipeline of new workers, and strong demand, the labor gap continues to grow. Robotic welding offers a sustainable way to close that gap.

One of the most important developments in recent years is how much easier robotic welding systems are to operate. With intelligent software and guided user interfaces, technicians no longer need deep programming experience to run a welding robot. Many systems allow operators to load a CAD model, set parameters, and start welding in just a few steps.

This means you can train team members from other areas, such as assembly or quality control, to operate a robotic welding cell with confidence. It lowers the barrier to entry and helps you remain productive even when hiring skilled welders becomes difficult.

Attract the Next Generation of Skilled Tradespeople

The skilled trades are evolving. Young workers are drawn to environments where they can work with cutting-edge technology, not just hand tools. Robotic welding helps position your shop as a modern, forward-thinking workplace.

Bringing automation into your welding process can make the job more attractive to younger candidates who value innovation and want to grow with the industry. Instead of spending full shifts performing repetitive manual welds, operators can oversee a robotic cell, analyze performance, and troubleshoot systems, all tasks that build long-term technical skills.

This shift also helps support career development. Team members trained on robotic systems often go on to become key contributors in programming, maintenance, or process optimization roles, giving you an internal pipeline of automation talent.

Increase Productivity and Weld While You Sleep

Robotic welding offers clear advantages when it comes to speed and consistency. Unlike human welders, robots don’t take breaks, get fatigued, or vary from one weld to the next. Once a part is set up and the process is dialed in, robotic welders can run with minimal supervision. Here’s how automation boosts productivity:

- Higher arc-on time: Robots maintain a consistent welding pace, maximizing deposition time.

- Faster weld speeds: Robotic arms can move precisely and quickly without sacrificing accuracy.

- Unattended operation: Many shops run robotic cells overnight, allowing for extra throughput without extra labor.

The result is a smoother workflow, better use of available space, and the ability to hit tighter deadlines with fewer resources.

Deliver Consistent Weld Quality, Every Time

When your reputation depends on clean, strong, and accurate welds, consistency is non-negotiable. Robotic welding excels in repeatability. Once a process is programmed and validated, the robot will execute the same movements with millimetric precision regardless of shift, operator, or workload. This leads to:

- Fewer defects and rework

- Higher customer satisfaction

- Easier compliance with welding codes and standards

Modern systems also include quality monitoring tools that track weld parameters in real time. This data allows you to catch issues early and make continuous improvements based on real-world performance. Whether you’re producing individual parts or small batches, robotic welding brings a level of control and predictability that’s hard to match with manual processes alone.

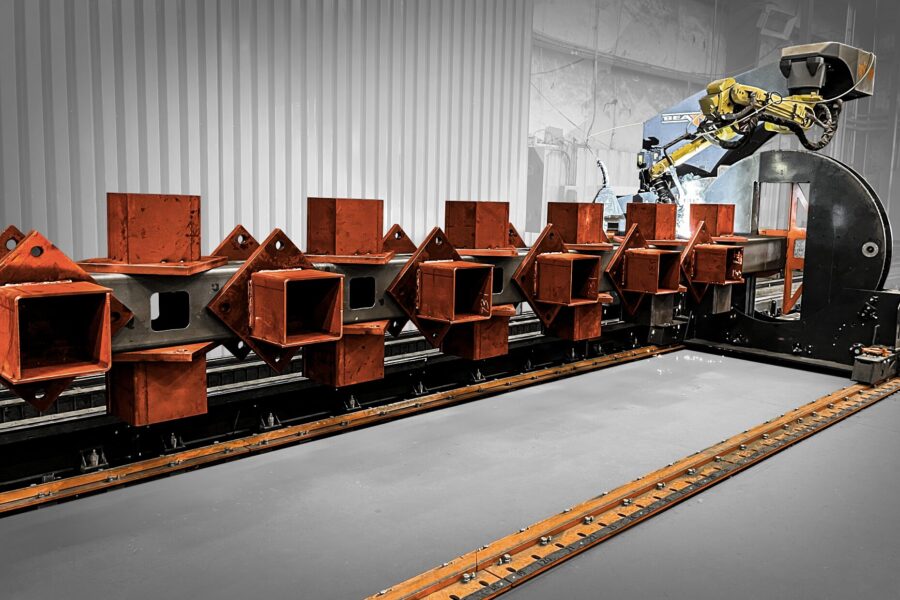

Adaptable and Modular Layouts for Any Shop Floor

One common misconception is that robotic welding systems require massive investments in space or infrastructure. The truth is, today’s systems are modular and designed to fit a wide variety of shop environments from compact single-station setups to multi-zone cells with long-track robots. Flexibility includes:

- Modular configurations: Choose the right number of zones, stations, or fixtures for your needs.

- Space-efficient layouts: Systems can be configured to fit around your existing workflow.

- Scalability: Start with one robot and expand later as demand grows.

Whether you’re outfitting a new facility or retrofitting an existing bay, robotic welding can be tailored to match your production flow. Integrators often work closely with fabrication shops to design layouts that maximize both space and efficiency without major disruption.

Final Thoughts

Robotic welding isn’t just about automation. It’s about solving real challenges that shops face every day from labor shortages and inconsistent quality to tight delivery timelines and space constraints.

Are you a shop owner or production manager considering robotic welding? Future-proof your operations, support your workforce, and build a more resilient production environment.

Whether you’re just beginning to lean into automation or looking to expand an existing setup, robotic welding can help you bridge the gap between today’s constraints and tomorrow’s opportunities.

Frequently Asked Questions

How difficult is it to train someone to operate a robotic welding system?

AGT Robotics systems are built for simplicity and ease of use. With Cortex, our auto-programming software, operators can go from CAD model to weld-ready program in just a few clicks, no coding required. Even team members without prior robotics experience can be trained quickly, making it easier to onboard new users and maintain productivity.

Can robotic welding work for smaller production runs or custom parts?

Absolutely. AGT’s Cortex batch processing engine can generate hundreds of robot programs automatically even for unique, one-off parts. Entire buildings or custom assemblies can be processed with little to no human intervention, making robotic welding viable for high-mix, low-volume workflows as well as larger production runs.

What kind of maintenance does a welding robot require?

AGT systems are designed for reliability and ease of maintenance. Preventive tasks such as torch cleaning, cable checks, and nozzle inspection are straightforward. AGT also offers remote diagnostics and real-time support, so your team can quickly resolve issues without extended downtime.

Which AGT system is best for beam fabrication?

– BeamMaster: Ideal for structural steel parts like beams and columns.

– BLOK: Flexible for high-mix, low-volume welding of heavy parts like trailers, trusses and skids.

These systems are recognized among the best welding robots for structural applications due to their adaptability and productivity.

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.