Myths about robotic welding that are holding back growth in the structural steel sector

This hesitation in betting on robotic welding doesn’t come from the technology itself, but from preconceived ideas that have been around for years. Fear of the unknown still influences important decisions and often ends up blocking company development. However, well-informed decisions not only help overcome long-standing barriers, but also reveal new growth opportunities.

In this article, we focus on the three most common myths and explain why continuing to believe them may be limiting the growth and stability of your production:

- Myth #1: Robotic welding doesn’t work in high-mix, low-volume production

- Myth #2: Robot Programming is too complex and creates new problems

- Myth #3: The investment in robotic welding is too high for small or mid-sized companies

Myth #1: Robotic welding doesn’t work in high-mix, low-volume production

This is probably the most common argument in the structural steel sector. And for a long time, it was true: robotic welding made sense mainly in highly repetitive environments, with large series and little variation, because each different part could require several hours of programming.

What has changed?

The world has evolved, and so have welding technologies. Every day, new equipment, new processes, and new production solutions appear. Yet it seems to be hard to accept that robotic welding has also evolved (and significantly in recent years).

Even though today’s reality is still high variety and relatively low volumes, robotic welding systems can now handle that challenge.

What used to require manual programming part by part, hours on a teach pendant, and constant intervention has been replaced by automated programming and vision systems. These technologies generate welding programs almost autonomously and adjust the path during production, without needing a full reprogram. This last point is especially relevant when we talk about beam welding, where each beam is slightly different from the previous one.

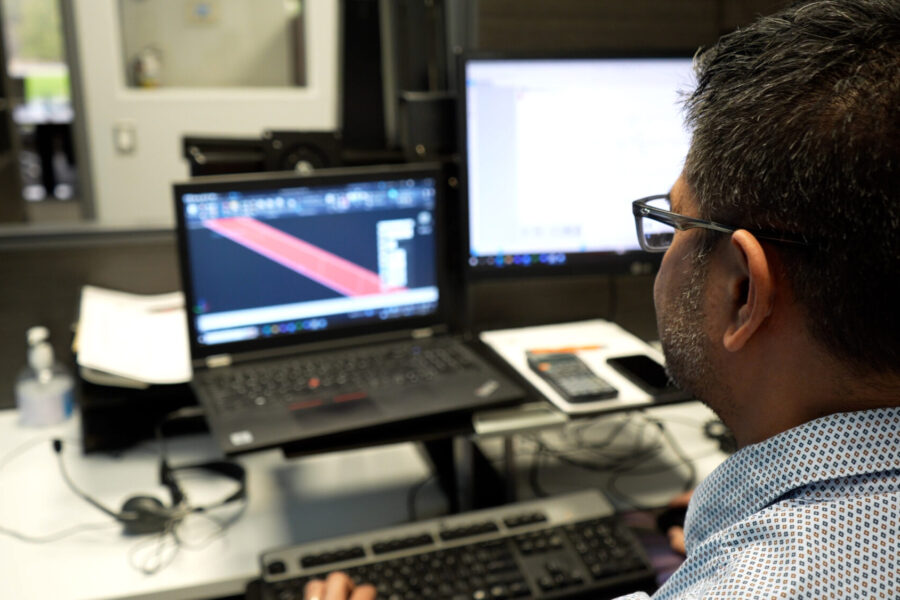

Welding software such as Cortex, developed by AGT, can process an entire building from a CAD file, defining parts, attachments, and welds, and selecting the best welding parameters from a large database. In addition, it runs simulations to avoid collisions and ensure smooth, continuous robotic welding operations, all with minimal human input and in just a few minutes.

This translates into something simple: fewer interruptions, fewer improvised adjustments on the shop floor, and more predictability.

Myth #2: Robotic Programming is too complex and creates new problems

After debunking the myth that robotic welding is not viable in high-variety, low-volume environments, the next question almost always comes up:

“I’ll eliminate the difficulty of finding welders, but will I create a whole new set of needs in my production. Am I just replacing one problem with another, and an even more expensive one?”

One of the biggest fears around robotic welding is exactly this: automation solves one problem but creates another, by relying on specialized programmers or complex systems. As mentioned earlier, for many years this concern was legitimate. Today, when you choose a solution aligned with the results you want to achieve, it no longer has to be.

More recent approaches, such as CAD-to-Weld workflows, show that automation can solve problems without creating new ones, by simplifying the processes associated with robotic welding.

In a system where the welding logic is generated directly from the digital model (for example, Tekla or IFC), steps such as manual programming part by part or constant trajectory validations are no longer required. In other words, you don’t need to hire a specialized programmer: any operator can be trained quickly to use the system because the software handles most of the actions.

This makes adopting a robot a simple and efficient process, without needing to hire new resources (or create new problems).

Myth #3: The investment in robotic welding is too high for small or mid-sized companies

Even today, many business owners and managers don’t even consider robotic welding, believing it “isn’t for them.” Low or inconsistent workflows over time reinforce the idea that the system is “too expensive and unlikely to deliver a return.” The problem is that by taking this belief, they risk being overtaken by competitors who approach robotic welding with the mindset of: “What if it works for me?”

When people look at robotic welding, they often assume it requires a large investment made all at once, frequently based on production that may be unstable. This rigidity creates risk: committing capital without knowing whether installed capacity will keep pace with changes in the order book.

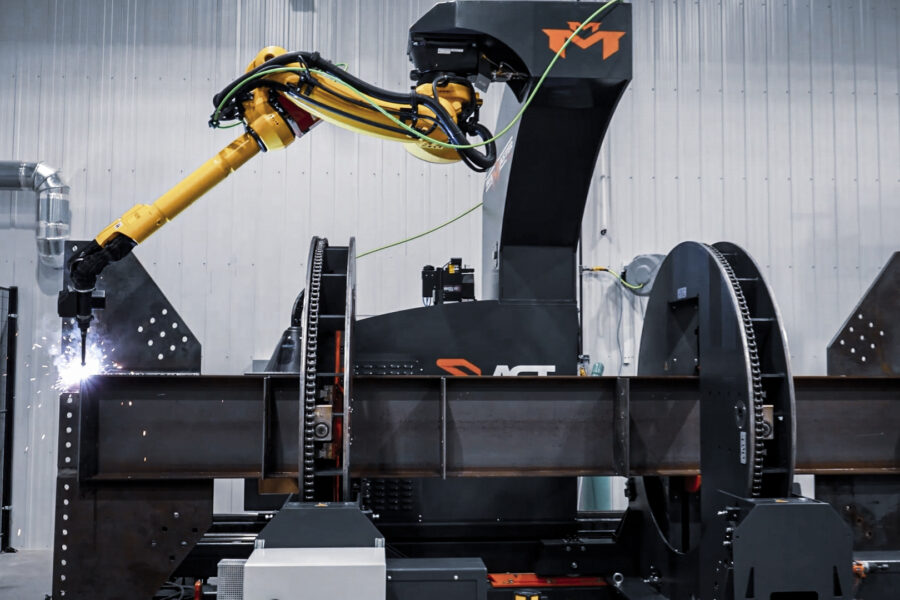

In practice, the relevant cost is not only the initial investment, but how well it can match the company’s real growth. Systems designed specifically for structural steel, such as BeamMaster, allow the investment to be made gradually, scaling at the pace of production. Instead of an “all or nothing” implementation, it is possible to start with a single robot and one welding zone focused on the most critical or repetitive operations, and expand from there as the business evolves.

As volumes increase, deadlines become more demanding, or the production mix changes, the same cell can grow in a controlled way by adding more robots or additional work zones within the same structure. This modularity reduces financial risk, supports internal learning, and allows the return on investment to track the maturity of the production process.

From a planning perspective, this approach gives the company flexibility to adjust installed capacity based on real data, not optimistic or defensive forecasts. Production becomes more predictable, pressure on teams decreases, and decisions can be made as the business evolves.

What happens when we abandon these myths: a practical example

Based on the company’s size and order book, many might assume that ETS Bobet, a French company in the structural steel sector, would be one of those businesses where “robotic welding wouldn’t make sense.” However, the company faced the typical challenges of the industry, such as a lack of qualified welders, high physical strain, and difficulty meeting deadlines.

When it came time to decide on the future of production, ETS Bobet ignored the myths and invested in robotic welding, specifically the BeamMaster system. The initial investment was a system with one robot and two zones, not only to cover existing needs but also to increase production volume, automate repetitive welds, reduce rework, and allow operators to focus on higher-value tasks.

The results leave no doubt about the effectiveness of this decision

- Welding time reduced: from 2 hours to 50 minutes per column — a 58% reduction

- Production increased: about 35% more volume, with consistent quality

- Greater reliability: ability to take on weekly contracts that previously were not possible

- Operator focus: welders now concentrate on higher-value tasks while the robot handles repetitive welds

This case shows that abandoning myths about robotic welding can bring higher productivity, predictability, and control, without overburdening the team.

BeamMaster: a perfect solution to clear all the myths about robotic welding

BeamMaster was developed specifically for structural steel welding (and to address all of these myths). Its relevance is not in generic promises, but in real day-to-day benefits for companies: flexibility for different part types, accessible programming, and a stable production process.

From a production standpoint, the value lies in reducing variability, making production times more predictable, and being able to plan with confidence. It isn’t about replacing people but supporting teams with a more controlled process that relies less on improvisation.

Fewer myths, more control

The goal is not to adopt technology for its own sake. It has to be adapted to a company’s challenges and growth objectives.

Reassessing myths about robotic welding is essential for informed decision-making. When applied properly, automation becomes a tool to gain control and, ideally, bring some peace of mind back to everyone involved in the process.

If you want to confirm whether robotic welding makes sense for your production, get in touch with our team of specialized technicians.

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.