Company Background

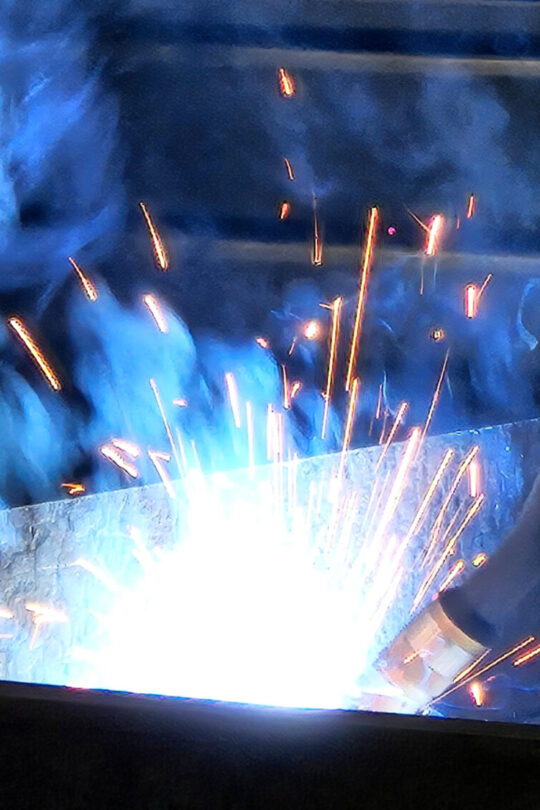

Based in Château-Gontier-sur-Mayenne, France, SERRU specializes in steel structures, metalwork, and aluminum joinery for industrial, tertiary, and agri-food buildings. As part of the ACIEO Group, the company employs nearly 200 people and supports its clients from design to full installation.

SERRU’s expertise lies in custom steel construction, serving demanding markets such as the agri-food industry, where quality and reliability are critical.

“On average, we process between 400 and 500 tons of steel each month in our workshops,” explains Julien Stochement, Production Manager. “Right now, most of our buildings are made with welded built-up beams, which represents a significant tonnage.”

The Challenge: Producing More With Less Workers

Like many companies in the steel fabrication sector, SERRU was struggling with a shortage of qualified welders and operators. In the southern Mayenne region, where unemployment is very low, finding skilled workers has become increasingly difficult.

“The robot isn’t here to replace people… it’s to make up for the ones we can’t hire,” says Vincent Poilvet, General Manager. “It can handle repetitive tasks that a human operator simply can’t perform continuously.”

At the same time, SERRU was pursuing strong sustainability goals including the use of low-carbon and recycled steel, the installation of solar panels, and the revitalization of green spaces around its facilities. The company sought a solution that would increase productivity while staying true to its values of responsibility and well-being.

The Solution: BeamMaster and Cortex

To address these challenges, SERRU partnered with AGT Robotics, a global leader in robotic welding systems for heavy fabrication.

The BeamMaster, powered by Cortex, was selected to automate long, repetitive welds and streamline the entire workflow.

Cortex automatically converts data from Tekla Structures into robot-ready welding programs, and no manual programming is required. From the first day of operation, the system could weld complex beams and assemblies right out of the box.

“The first parts we simulated were welded fifteen minutes later without any programming.” — Julien Stochement, Production Manager

SnapCam : Extra Performance

SERRU also added the SnapCam vision system, which quickly detects weld seams and reduces scan times by a factor of three to four.

This innovation alone contributed to a 20–25% increase in their productivity.

Redefining Roles: From Welders to Assemblers

Rather than replacing welders, the BeamMaster has redefined their roles. Welders have become assemblers, focusing on setup, fit up, and finishing while the robot takes care of long welds with perfect consistency.

“We’ve turned our welders into assemblers. The robot handles the long welds while operators focus on upstream assembly work.” — Julien Stochement

This new approach has freed up skilled labour for higher-value tasks and allowed SERRU to run nearly 24-hour continuous production. The robot works autonomously through the night, with teams rotating to keep production flowing.

“The robot runs completely autonomously until three in the morning. When the morning shift comes in, they change the parts and restart. Production just keeps going.”

As a result, SERRU has achieved a 10% increase in total capacity, higher productive hours per month, and a significant reduction in subcontracting.

A Smooth Integration and Strong Partnership

From installation to training, the integration process was seamless. AGT Robotics worked closely with SERRU to ensure a fast, confident transition to automation. Training sessions allowed operators to master LayoutMaster and Cortex before the robot even arrived on-site.

“The support from AGT and the relationship we’ve had since day one have been excellent.” — Julien Stochement

“Whenever we submit a support ticket, we get a quick and detailed response. The service works really well.” — David Bélanger, Simulation & Planning

Within weeks, SERRU’s team was able to simulate weld paths, plan production, and operate the robot independently.

Measurable Results

After just 18 months of use, the results speak for themselves:

- +10% increase in production capacity

- 20–25% productivity gain with SnapCam

- Reduced subcontracting

- Continuous day-and-night operation

- Return on investment in under five years

“We’ve exceeded our original projections. The BeamMaster will be fully paid off within five years.” — Julien Stochement

Beyond performance, SERRU has achieved greater stability, improved safety, and higher employee satisfaction.

“The robot is faster than a human and it never gets tired!” — Florian Rezé, Robot Operator

Building a Sustainable Future Through Automation

For SERRU, automation is not just about productivity; it’s about building a sustainable and resilient future. The company’s approach combines technological innovation with environmental responsibility and human empowerment.

“The robot impressed us from the very beginning. We completed the project on time, at a speed we never imagined.” — Vincent Poilvet

Conclusion

SERRU’s story proves that robotic welding and fabrication automation can deliver measurable results not by replacing people, but by enhancing their potential. With the BeamMaster, Cortex, and SnapCam, SERRU has achieved faster production, stronger quality, and smarter use of its workforce.

Automation, when done right, isn’t about machines taking over. It’s about helping people and businesses reach new heights.

Hear It In Our Customer’s Own Words

Watch the full video testimonial to see how SERRU transformed its steel fabrication process with the BeamMaster and Cortex.

Disclaimer:

SERRU is a France-based company. The original interview was conducted in French and has been dubbed in English using AI for accessibility. To view the original French version, click here.

Ready To Take Your Welding To The Next Level?

The BeamMaster Is The Solution

Discover how the BeamMaster can automate your welding process, increase productivity, and make your fabrication shop more competitive.

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.