Society has changed. There are fewer welders, and many skilled workers are getting older. To work faster and do more, manufacturers need to look for other options, and robotic welding has been at the center of this.

More than a “trend,” robotic welding is now a strategic move to meet the sector’s demands. Even for smaller companies, the cost of not having a robotic system is becoming higher than the cost of investing in one.

The structural steel sector is changing...

According to the American Welding Society (AWS), there will be a shortage of about 360,000 welders in the United States by 2027. In Europe, the situation is similar, with estimates showing a lack of over 200,000 welders by 2030. One big reason is that young people are less interested in old industrial jobs. They often look for work in digital fields instead.

The aging workforce makes this problem worse. In the European Union, the average welder is over 45 years old, while in the United States it is around 55. This means more than half of the skilled welders are near retirement, so the companies are risking loss of knowledge and experience. This puts more pressure on companies to find solutions to make up for fewer welders.

Market demand is higher

There is a need for faster responses and the parts are getting more complex and demanding. But manual welding has limits: it takes a lot of time and skill, making big productivity gains hard without hiring more welders.

That is why robots are becoming more attractive. They can work many hours with the same precision and quality. It allows short cycles and with fewer mistakes, without needing to hire more welders who are hard to find. For companies, this means faster project delivery and less time and money wasted fixing errors.

Robotic welding systems are also changing...

These changes in the structural steel industry aren’t new. Yet, until now, robotic welding systems have not been very attractive due to the high programming time required. Low volumes and many different parts, common in the structural steel world, meant long hours of programming, making it difficult to reduce cycle time compared to manual welding. Additionally, hiring robot programmers is challenging, and when they leave, their knowledge leaves with them.

But this is old news now… Auto-programming is changing the game.

Auto-programming means that the robot can program itself with minimal or zero human intervention. This shifts completely the perception of robotic welding systems in the structural steel industry, making them the go-to solution for improving productivity and quality.

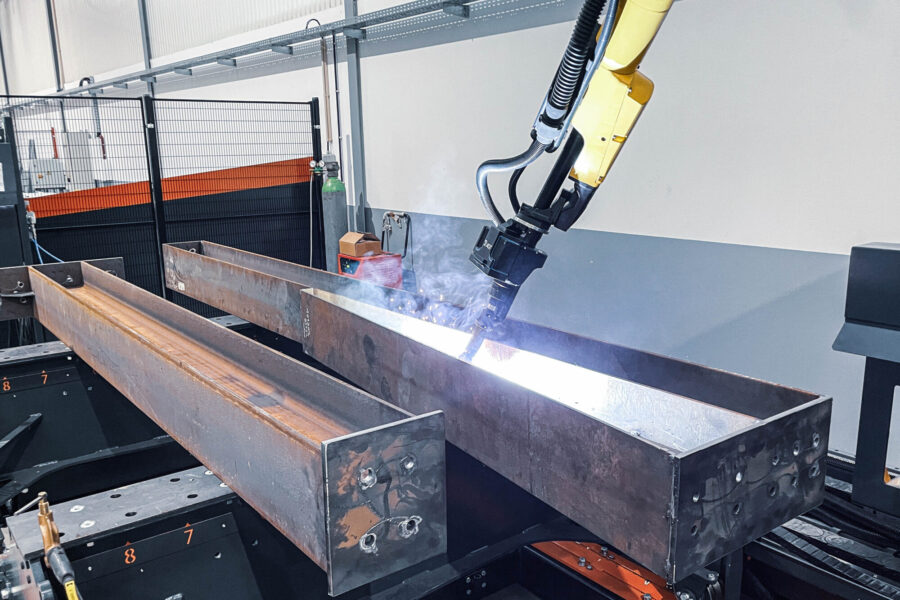

Systems like the BeamMaster, developed by AGT Robotics, use its home-made unique auto-programming software called Cortex to create welding paths in minutes instead of hours. Simply send a pre-fit beam to the machine, and it completes the welds much faster than manual work. The combination of the Cortex with the BeamMaster makes robotic welding affordable, even for small companies, and doesn’t require many identical parts.

Because no programmer is needed, any operator can use it, helping to reduce the demand for skilled workers. On average, in the structural steel industry, the BeamMaster can replace up to three manual welders.

But do these systems also work for small companies?

The BeamMaster is a modular system that can grow with the company. This is crucial for small manufacturers who can’t make big investments all at once. With our robotic welding system, companies can start with one robot and one workstation, then add more robots and workstations as they grow.

The new era of robotic welding for structural steel

The industrial reality for structural steel manufacturers is changing. Factories need to prepare to make sure they stay competitive.

Robotic welding systems won’t solve 100% of problems, but they can handle repetitive and physically hard tasks that often tire welders. This lets welders focus on higher-value work for the company.

There are fewer workers, higher productivity needs, and plans to grow. Because of this, steel fabricators should look at their business and take the next step before their competitors do.

For many, robotic welding is the answer. What will yours be?

If you want to learn more or are ready to take the next step, book a demo with our team now!

Latest AGT News

Stay informed with our in-depth articles on the latest innovations and developments in the world of robotics and automation.